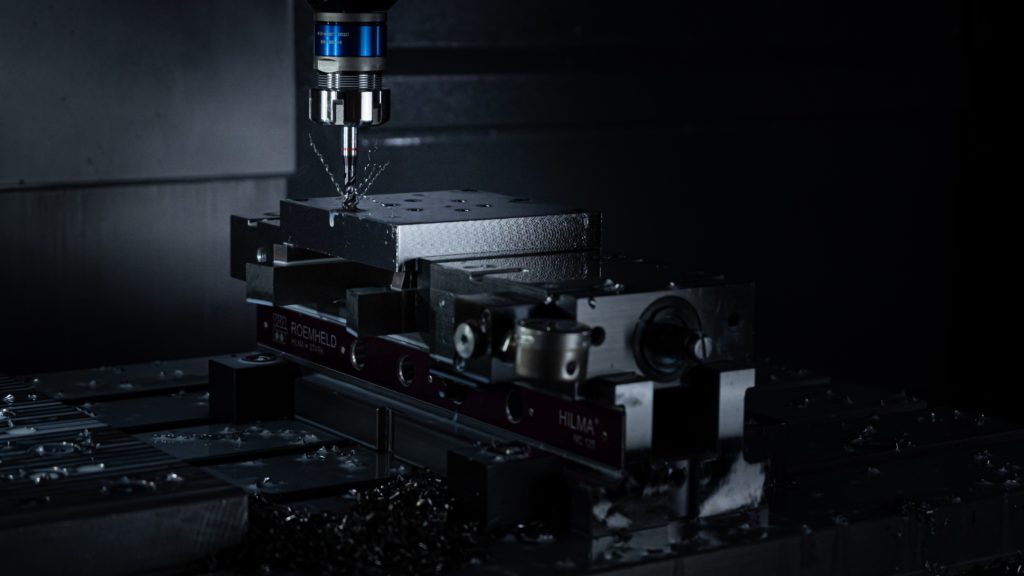

CNC machining, or Computer Numerical Control machining, has revolutionized the manufacturing industry. This technology augments traditional milling and drilling methods, allowing for greater precision and customization, more efficient production, and higher quality finished products. CNC machining has become a vital component in the production process of many industries, including aerospace, automotive, medical, and consumer electronics.

At the forefront of CNC machining technology is Huayi International Industry Group Limited, also known as Huayi Group. Established in 1988 in Hong Kong, Huayi Group has become a leading provider of CNC machining solutions, manufacturing different types of Grinders, CNC lathe machining parts, CNC milling parts, metal stamping parts, springs, wire forming parts, and more. Their reputation for quality and precision is seen in the fact that their factories have been certified by ISO9001, ISO14001, and ISO/TS16949.

Huayi Group's success and impact on the industry is not unique. CNC machining has quickly become the preferred method for manufacturers across the globe, with companies investing in CNC machines in order to streamline their production process and improve the quality of their products. The benefits of CNC machining include:

1. Precision - CNC machines use a computerized system to cut and shape materials into precise shapes and sizes, ensuring that each product is uniform and of the highest quality. The level of precision provided by CNC machines is unmatched by traditional techniques.

2. Customization - CNC machining allows for the creation of complex shapes and designs that cannot be replicated with traditional methods. This makes it an ideal choice for manufacturing products that require intricate details and unique shapes.

3. Efficiency - CNC machines can operate with little human intervention, reducing the time and effort required for the manufacturing process. This can result in decreased production time, increased output, and lower costs.

4. Repetition - CNC machines can produce multiple copies of the same product with absolute consistency, eliminating the risk of human error and ensuring that every product is identical.

CNC machining has also had a significant impact on industries such as aerospace and automotive. The precision and accuracy provided by CNC machines allows manufacturers to create parts that are both lightweight and durable, with complex shapes that are essential for proper function. The medical industry has also benefited greatly from CNC machining, where precision and accuracy are critical for creating implants and medical devices.

As the demand for CNC machining continues to grow, so too does the need for skilled workers who are familiar with the technology. In response, many schools and training programs have added CNC machining to their curriculums, providing a new generation of workers with the skills necessary to operate CNC machines and work in the manufacturing industry.

In conclusion, CNC machining has become an essential component in modern manufacturing. Its precision, customization, efficiency, and repetition capabilities have revolutionized the industry, resulting in faster production times, increased output, and higher quality products. Companies like Huayi Group are leading the charge for CNC machining, providing solutions that meet the needs of a wide variety of industries. As the industry continues to evolve, the importance of CNC machining will only continue to grow, providing exciting opportunities for manufacturers and skilled workers alike.